Zirconia Ceramic Foam Filter for steel casting

Price 1.0 USD ($)/ Carton

MOQ : 10 Cartons

Zirconia Ceramic Foam Filter for steel casting Specification

- Surface Treatment

- sintering

- Usage

- steel casting

- Type

- Ceramic filter for casting

- Size

- 50*50*15

- Material

- zirconia

- Height

- 15 Millimeter (mm)

- Product Type

- zirconia Foam ceramic filter

- Weight

- 150 Grams (g)

- Color

- yellow

- Function

- Filter impurities

- Length

- 50 Millimeter (mm)

- Width

- 50 Millimeter (mm)

- Application

- steel casting

Zirconia Ceramic Foam Filter for steel casting Trade Information

- Minimum Order Quantity

- 10 Cartons

- FOB Port

- Qingdao port

- Payment Terms

- Delivery Point (DP), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Letter of Credit (L/C)

- Supply Ability

- 1000 Cartons Per Month

- Delivery Time

- 30 Days

- Sample Available

- No

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

- Packaging Details

- cartons and pallets

- Main Export Market(s)

- Asia, Australia, North America, South America, Eastern Europe, Central America, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- ISO9001

About Zirconia Ceramic Foam Filter for steel casting

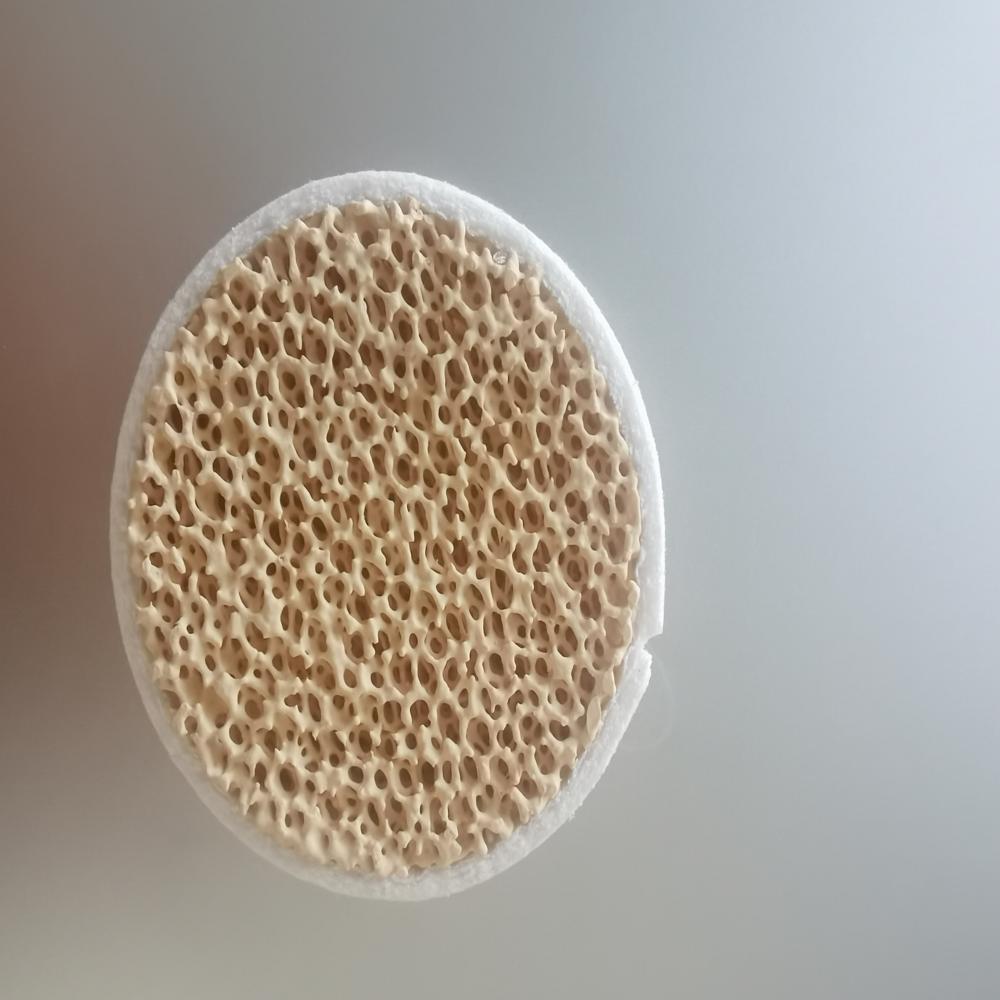

Zirconia Foam Ceramic Filter

A zirconia-based foam ceramic filter is a high-performance porous material manufactured by coating zirconium oxide (ZrO) ceramic slurry onto a three-dimensional reticulated organic foam carrier, followed by drying and high-temperature sintering6. This structure provides exceptional thermal stability (withstand temperatures up to 1700C) and chemical resistance, making it ideal for molten metal filtration in casting processes25.

Key features include:

High porosity and uniform pore distributionto effectively capture inclusions (slag, oxides) in steel, iron, copper, and aluminum alloys28.

Enhanced mechanical strengthcompared to traditional alumina or silicon carbide filters, improving durability under extreme conditions56.

Reduced casting defectssuch as sand holes and gas porosity, significantly lowering scrap rates in industrial production8.

Widely used in foundries for automotive, aerospace, and machinery components, it ensures cleaner molten metal flow and improved product quality.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Metallugical Refractory Category

Metallugical Refractory

Minimum Order Quantity : 10 Pieces

Material : Stainless Steel

Color : Black

Surface Treatment : Polished

Features : High quality

High Alumina crucible for metal melting

Price 20.0 USD ($) / Piece

Minimum Order Quantity : 1000 Pieces

Material : High alumina

Send Inquiry

Send Inquiry