RV Reducers for Robotic Systems

Price 100000.0 INR/ Unit

RV Reducers for Robotic Systems Specification

- Control System

- Manual

- Features

- Good Quality

- Country Of Origin

- India

- Product Type

- Gear Reduce

- Surface Treatment

- Coated

- Color

- Silver

- Warranty

- 1 year

RV Reducers for Robotic Systems Trade Information

- Minimum Order Quantity

- 100 Units

- FOB Port

- Qingdao

- Payment Terms

- Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

- Supply Ability

- 10000 Units Per Month

- Delivery Time

- 30 Days

- Sample Available

- No

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Wooden box and pallets

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- ISO

About RV Reducers for Robotic Systems

Here's a focused technical introduction to RV reducers for robotics applications:

RV Reducers for Robotic Systems: High-Precision Power Transmission Redefined

The RV (Rotary Vector) reducer represents a pinnacle of precision gearing technology, specifically engineered to meet the rigorous demands of industrial robots, automated manufacturing systems, and high-payload automation equipment. Combining cycloidal drive principles with planetary gear advantages, RV reducers deliver unmatched torque capacity and positioning accuracy in compact packages.

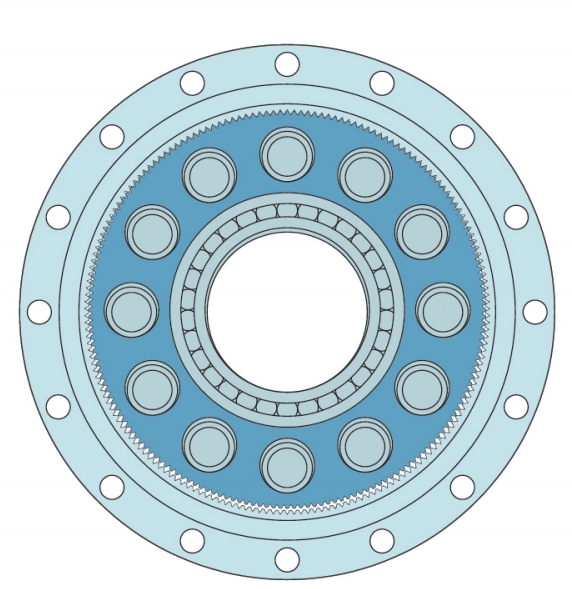

Core Architecture & Working Principle:

-

Dual-Stage Transmission System

- Primary Stage: Planetary gear unit for initial speed reduction

- Secondary Stage: Cycloidal pinwheel mechanism converting eccentric motion into concentric rotation

-

Eccentric Motion Conversion

- Rotor-mounted crankshaft drives two cycloidal discs through 180 phase-shifted eccentric cams

- Needle roller bearings enable smooth transformation of eccentric rotation into balanced output torque

-

Force Distribution Mechanism

- Multiple contact points across cycloidal disc teeth and pin gear

- 2-3x higher shock load absorption compared to conventional gear systems

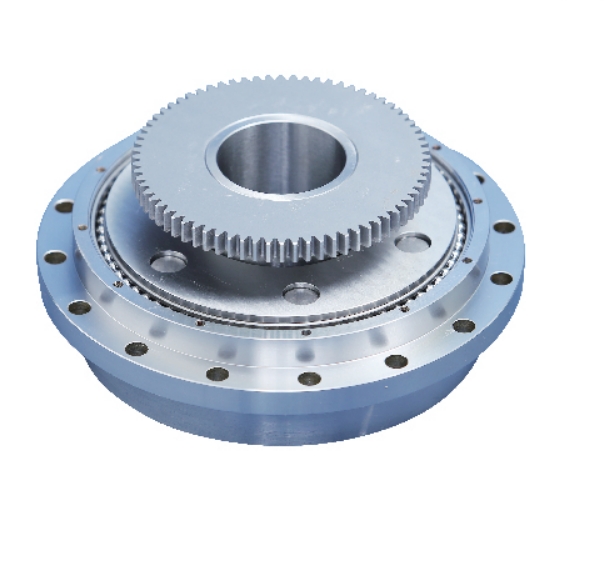

Material & Manufacturing Excellence:

- Case-Hardened Alloy Components: 20CrMnTi steel gears with 58-62 HRC surface hardness

- Ultra-Precision Grinding: Achieves tooth profile accuracy 1 arc-minute (ISO 1328 Class 1)

- Integrated Bearing Design: Cross-roller bearings built into reducer housing for direct load support

Performance Superiority:

- Torque Density: 2.5-3.5 Nm/kg ratios outperforming harmonic drives in heavy-load scenarios

- Zero-Backlash Maintenance: <0.5 arc-minute hysteresis through preloaded needle roller assemblies

- Impact Resistance: Sustains 300% momentary overload capacity critical for spot welding robots

- Thermal Stability: 0.03 positioning drift per 10C temperature variation

Key Applications:

- Articulated robot joints (Axis 1-3 in 6-axis industrial robots)

- Automotive assembly line transfer systems

- Precision machine tool rotary tables

- Heavy-payload AGV steering mechanisms

- Aerospace component positioning fixtures

Technical Benchmarking:

| Torque Range | 50-5,000 Nm | 10-500 Nm |

| Positioning Repeatability | 0.01 | 0.03 |

| Shock Load Tolerance | 300% | 150% |

| Service Interval | 12,000-15,000 hr | 8,000-10,000 hr |

Innovation Frontiers:

- Hybrid ceramic-steel composite cycloidal discs for space robotics

- Integrated torque sensors with CAN bus communication

- Oil-free lubrication systems for food/pharmaceutical automation

- AI-driven wear prediction through vibration signature analysis

Superior Quality and Engineering

These RV Reducers are manufactured using advanced techniques and material selection, ensuring a high standard of performance suitable for demanding robotic applications. Each piece features a durable coated surface for enhanced longevity and resilience in varied environments.

Wide Distribution Network

As a leading manufacturer, supplier, exporter, and trader in India, we offer these premium RV Reducers to clients across national and international markets. Our wide distribution ensures timely availability and support, regardless of location.

FAQ's of RV Reducers for Robotic Systems:

Q: How do RV Reducers improve the efficiency of robotic systems?

A: RV Reducers enhance robotic systems by delivering precise motion control and torque transmission, resulting in smoother operations and greater positional accuracy. This boosts both productivity and reliability in automation environments.Q: What warranty coverage is provided for these RV Reducers?

A: Each RV Reducer comes with a one-year warranty, giving you peace of mind regarding manufacturing defects and guaranteeing product reliability over this period.Q: When should RV Reducers be serviced or replaced?

A: It is advisable to perform routine inspections according to your robotic system's maintenance schedule. Although these reducers are designed for longevity, monitor them for signs of wear and schedule replacements or servicing as needed to maintain optimal performance.Q: Where are these RV Reducers manufactured?

A: Our RV Reducers are proudly manufactured in India, adhering to stringent quality standards to ensure performance and durability over extended use.Q: What is the process for ordering RV Reducers in bulk?

A: As a manufacturer, distributor, and exporter, we cater to both bulk and individual orders. Contact our sales team with your requirements; we will guide you through the quotation, ordering, and delivery process to ensure efficient fulfillment.Q: How are these RV Reducers controlled and operated?

A: These reducers feature a manual control system, allowing operators to directly manage the motion parameters and make adjustments according to specific application needs.Q: What are the main benefits of the coated surface treatment on these reducers?

A: The coated surface treatment enhances resistance to corrosion and wear, ensuring the reducers maintain their integrity and performance even in challenging industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Gantry Machine Category

Insulating glass machine production line

Price 50000.0 USD ($) / Set

Minimum Order Quantity : 1 Set

Operating Type : Semi Automatic

Control System : SemiAutomatic

Power Source : Electricity

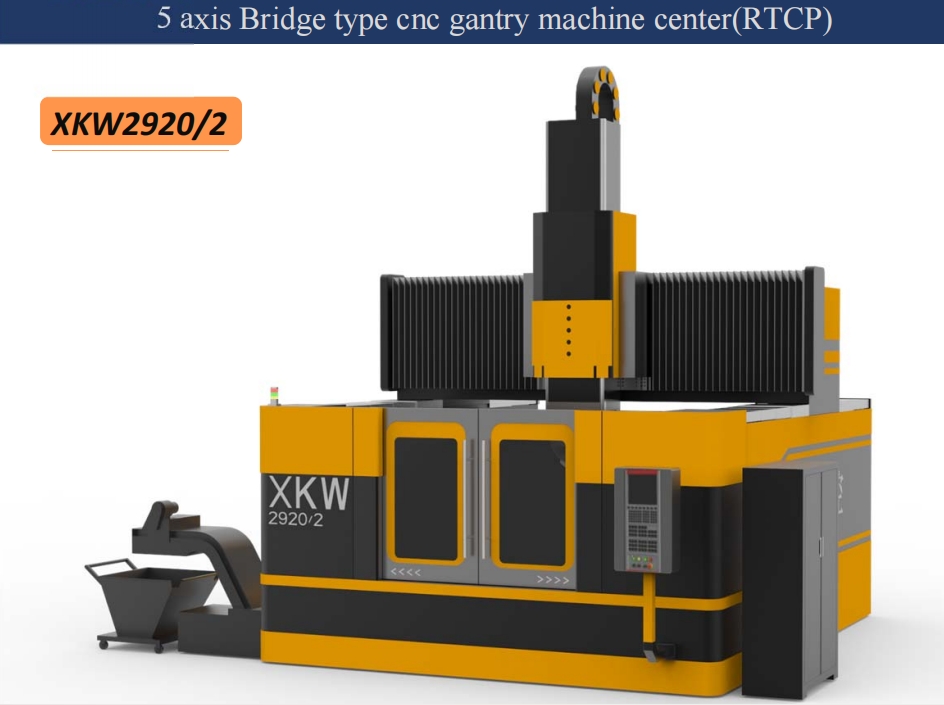

5 axis Bridge type cnc gantry machine center(RTCP)

Price 1000000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Operating Type : Automatic

Control System : Fully Automatic

Power Source : Electricity

Used plano milling CNC machine 4000*1800*1500mm

Price 62000.0 USD ($) / Set

Minimum Order Quantity : 1 Set

Operating Type : Automatic

Control System : Fully Automatic

Power Source : Electricity

Product Type : Milling Machine

CNC bridge gantry vertical machine center

Price 100000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Operating Type : Automatic

Control System : CNC

Power Source : Electricity

Product Type : Crushing Machines

Send Inquiry

Send Inquiry